How to Stop Flash

05.05.2025The Troubleshooter: Developing Robust Maintenance Procedures in Plastic Injection Molding Operations

Unplanned downtime erodes customer confidence and profits. Follow these simple steps to implement a planned maintenance strategy.

At a Glance

- Order parts in advance and have all tools in place before shutting down the press.

- If repairs exceed 30% of press value in a year, it’s probably time to buy a new machine.

- Tracking historical data is critical to an efficient maintenance approach.

Plastic injection molding efficiency is dependent on the ability of a molder to control and reduce unplanned downtime. A chaotic maintenance strategy leads to scheduling failures, erosion of customer trust, and reduced profits. This article will explain the difference between planned and unplanned downtime. It will also provide insights into ways to reduce down time and explain how to turn unplanned maintenance into a planned maintenance strategy.

Planned maintenance.

Planned downtime events are developed based on prediction and frequent inspection. Plants using a truly methodical approach will achieve better control of their maintenance approach. Parts are ordered for a planned event in advance, so lead times are known, which helps develop the repair/replace plan. An evaluation of needed tools and equipment is completed prior to the event, and all tools are in place before the press is shut down.

Unplanned maintenance.

Unplanned maintenance is often the result of a “fix it when it breaks” mentality. Technical support scrambles to develop a plan to make repairs. Parts quite often require expedited ordering. Some parts have lead times of four to 12 weeks, leaving the press disabled and the scheduler frantically looking for similar presses to make up for the handicap. Shorter runs and more mold changes are often the result, leading to increased scrap and larger downtime numbers.

Fleet age and condition.

Press age and condition are huge identifiers of whether press replacement is needed and required. As a general rule, presses that are more than 10 years old are reaching the age of retirement and should be monitored frequently. This does not negate the possibility of a five- to 10-year-old machine showing signs of age. If press repairs exceed 30% of press value in a year, it is likely that a replacement is needed. Older presses become unreliable and result in chaos in terms of productivity and efficiencies. You can have the best maintenance team in the world and still fail if your press fleet is weak and breaking down frequently.

Machine historical data.

Tracking machines’ historical data is critical to an overall maintenance approach. Predictive maintenance relies upon this data to determine the frequency of needed repairs from a planned event perspective.

Inspection frequency.

It is important to note that the industry has established basic industry frequencies for the inspection and replacement of press components. Bear in mind, though, that these standards do not specifically outline the needs of the presses in your plant! Like people, presses have their own identities, and maintenance logs need to be consulted for proper identification of frequencies and approach.

A strong maintenance approach requires frequent analysis and planning for each press. Planned and predictive maintenance is based on visual inspection, process monitoring, and historical data as it relates to each individual press. Eliminating unplanned maintenance is key to high quality, full utilization of available machine time, and higher profits.

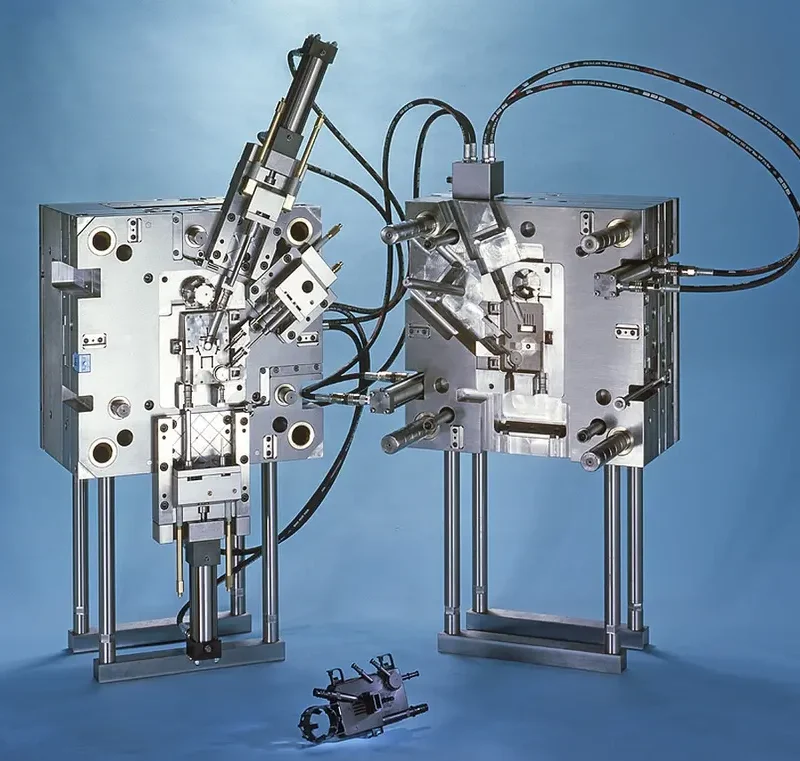

Portfolio

Our works

Contact us