Process

Home | Process

Step 1

Preliminary design activities

Every project begins with an idea for a desired product or part, a sample, a drawing or specifications for it. At this stage a Spetztekhosnastka Project Manager develops a project proposal, providing estimates of time and costs for the development and manufacture of molds. After the contract is agreed and signed, the Spetztekhosnastka Project Team for Tooling develops a detailed design and production schedule, which allows the parties to track the progress of the mold production.

Step 2

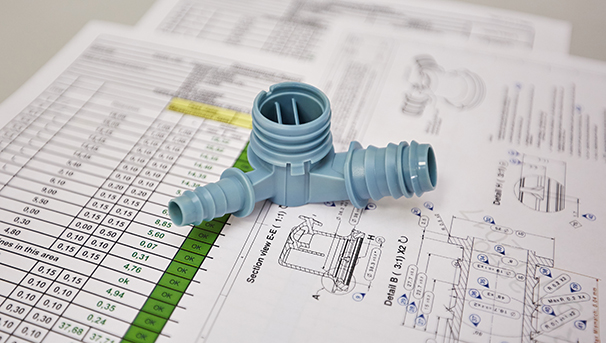

Injection mold design

Spetztekhosnastka Design Bureau consists of 17 highly qualified design and process engineers. Based on the approved technical specifications and schedule, a designer develops 3D models and mold drawings using SOLIDWORKS. Communication with the customer and design approval by the customer is a part of this process. All information related to the approved design, any changes and corrections made, are archived, and allow Spetztekhosnastka to manufacture any spare parts during the mold life in the future.

Step 3

Procurement

Upon final approval of the mold design, all needed materials and components are ordered by the procurement team. Spetztekhosnastka Tooling Shop uses BOHLER steels, AMPCO bronze, THYSSEN KRUPP aluminum alloys to produce mold parts. In addition to the mold parts manufactured by the Tooling Shop, the mold consists of standard components as well. Spetztekhosnastka purchases standard elements and systems from well-known manufacturers and suppliers such as DME, HASCO, HUSKY, STRACK, VEGA, BOLEX, FIBRO, and others.

Step 4

Production

The Spetztekhosnastka Tooling Shop produces mold components based on the 3D models and 2D drawings supplied by Design Bureau. About 60 skilled workers operate a variety of metal-cutting equipment, including 16 CNC machines. The equipment comprises universal turning and milling machines, vertical and radial drilling machines, surface grinding and cylindrical grinding machines for internal and external gringing, coordinate boring machines, and others. For electrical discharge machining (EDM), wire-cutting erosion machines and electrode-piercing erosion machines by CHARMILLES (Switzerland), and laser welding are used. CNC Machining Centers by top European manufacturers such as DMG (Germany), HERMLE (Germany), TAJMAC-ZPS (Czech Republic) ensure 3-axis and 5-axis machining of parts. CAM programs are developed with PowerMILL Pro by Autodesk.

Step 5

Heat treatment

For many years Spetztekhosnastka has been using a vacuum furnace to achieve desirable outcomes in steel normalizing and hardening. Our heat-treatment area is equipped with SECO / WARWICK 10.0 VPT-4025/24 vacuum oven.

Step 6

Grinding

Hardened parts are processed on the grinding machines. Spetztekhosnastka Workers of Spetztekhosnastka's Tooling Shop are equipped with various types of grinding machines and have decades of professional expertise and skills. Round outer, round inner, flat, profile, and thread grinding operations are performed with high precision.

Electrical Erosion

Step 7

One of the high-precision process operations is electro-erosion machining (EDM). Spetztekhosnastka has been successfully using it since 1995 in the cases when traditional methods of metal machining are not sufficient for achieving the desired result.

Step 8

Measurements

Parts’ dimensions are controlled by the Measuring Laboratory of Spetztekhosnastka Tooling Shop, equipped with modern coordinate-measuring machines, such as VISTA CMM (Carl Zeiss), Scope Check video measuring machine (WERTH), Scope Check MB CMM (WERTH) for profile and surface scanning. At workplaces, workers use universal measuring instruments as well as TESA electronic meters, ETALON micrometers, Mahr calipers, TESA calipers of various types and sizes.

Step 9

Assembly

The fitting and assembly area of Spetztekhosnastka Tooling Shop is the place where hundreds of manufactured and purchased parts are put together into a finished mold. Skilled and experienced toolmakers check and polish parts, and assemble the mold, ensuring the reliability of all components and systems.

Step 10

Testing

Testing a mold on an injection-molding machine is an essential step in mold-making. We use modern western European machines produced by DEMAG, ARBURG, and HUSKY to check the ease of installation and removal of the mold; the correctness of connections and accuracy of injection, thermal stabilization, ventilation, safety system; parts movement with pneumatic and hydraulic cylinders, the correctness of functioning of the hot runner system. The testing is performed both in setup mode and in serial production mode according to parameters required by the customer.

Mass Production

Step 11

In many cases, molds made by Spetztekhosnastka, remain at our site and are used for mass production of plastic packaging and plastic parts manufacturing for the needs of our customers. Over the years of production, we have become a reliable partner for a large number of companies, including such well-known names as RAVAL, Premium Sound Solutions, SodaStream, Kostal, DANONE, TRIORA, Agrinol, MGF, Kompozit, Dufa, ZIP, Torchyn, Schedro, Olis, Olkom.

Contact us